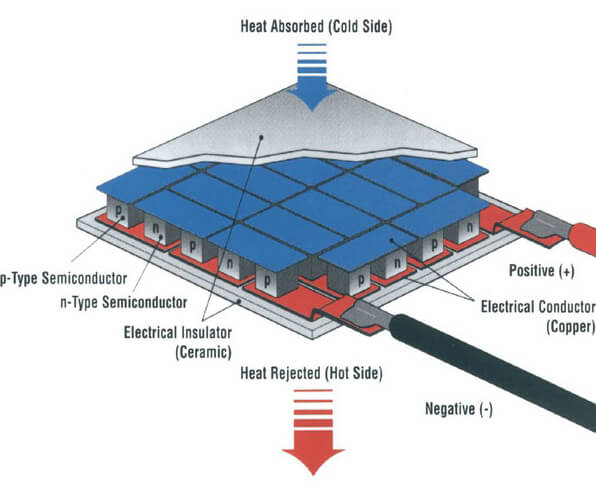

High thermal conductivity aluminum nitride cermaic insulation substrate product introduction aluminum nitride ceramic thermal plate high thermal conductivity low coefficient of expansion high strength high temperature resistance chemical resistance high resistivity low dielectric loss is the ideal lsi heat dissipation board and packaging materials aluminum nitride ceramic plate use.

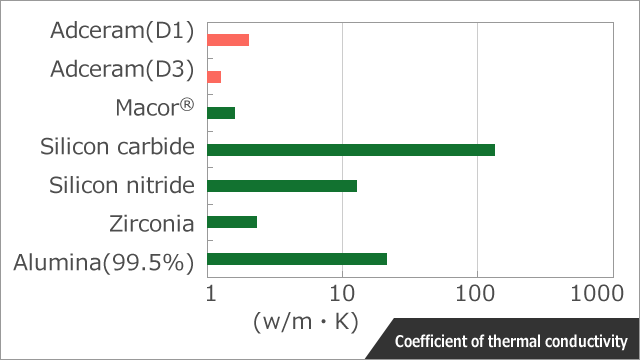

Ceramic plate thermal conductivity.

An average thermal conductivity of 5 077 w mk was obtained for bisque fired alumina which is exactly within the accepted thermal conductivity range of 5 to 5 25 w mk for this material.

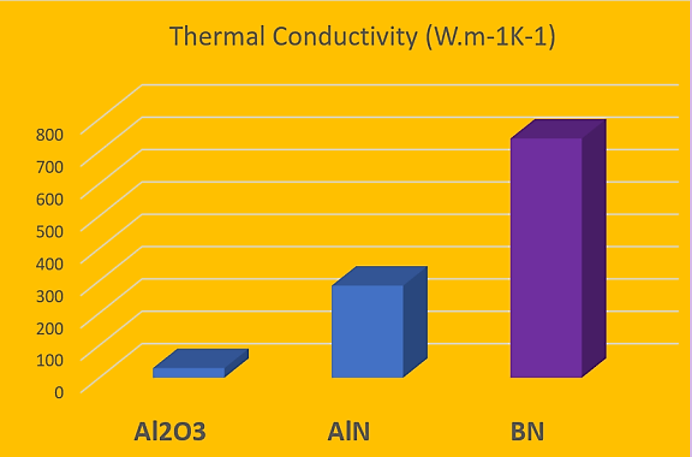

Denka an plate boasts thermal conductivity characteristics seven times greater than that of traditional alumina.

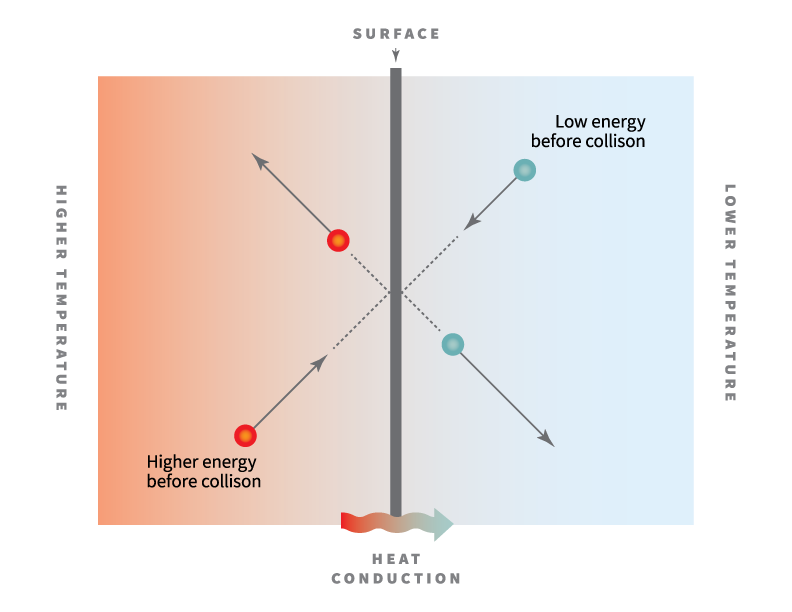

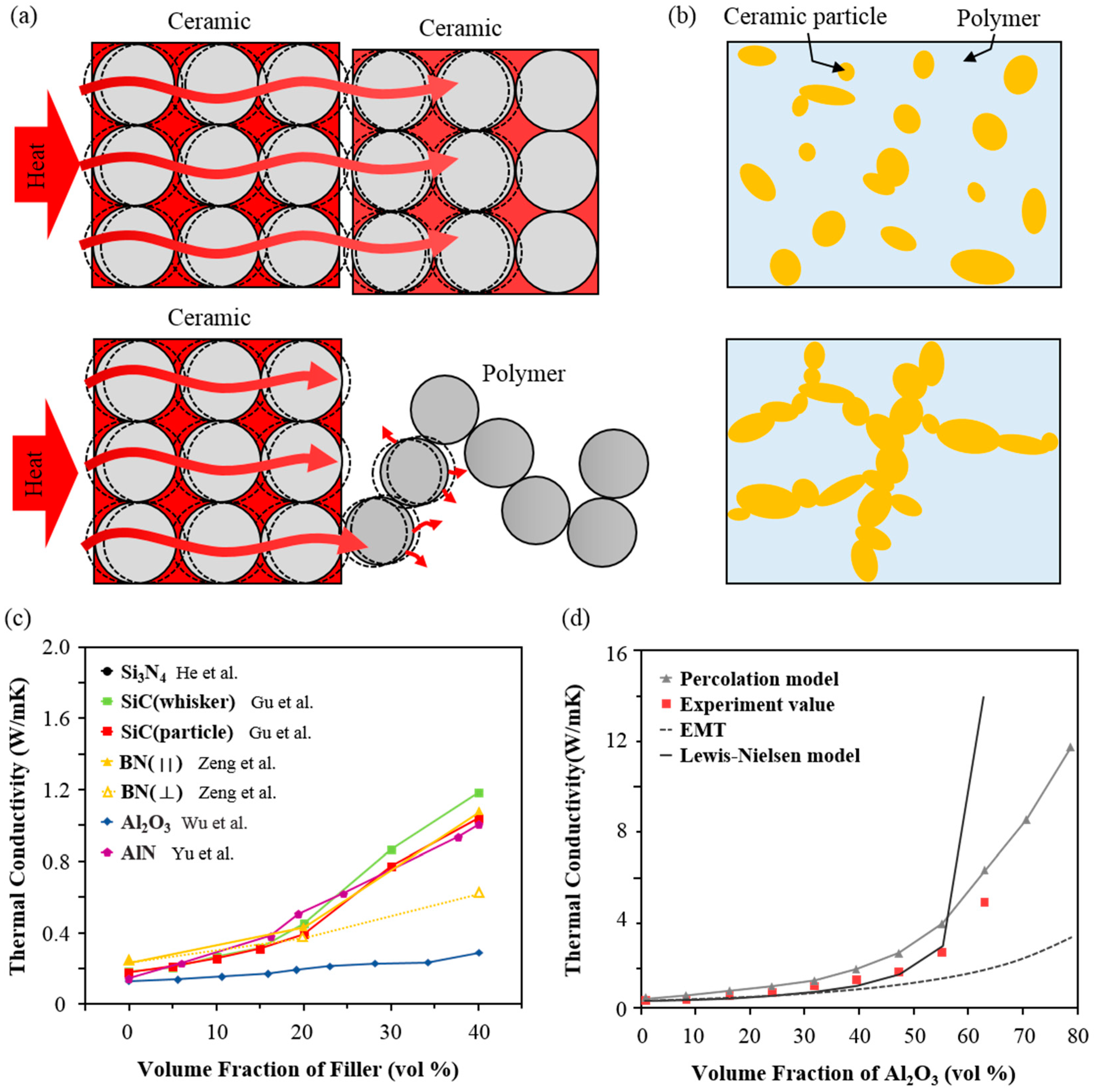

In a certain range increasing the thermal conductivity of ceramic materials by specific methods will improve its ability of heat conduction heat convection and heat radiation so as to further expand its application field.

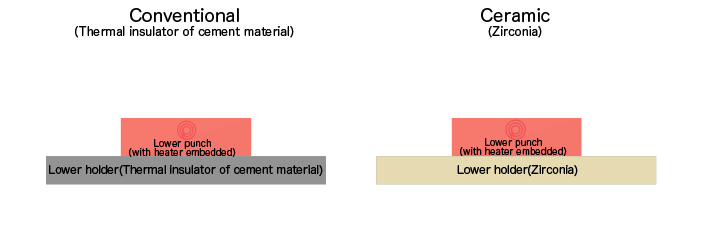

Low thermal conductivity great thermal shock.

The thermal conductivity of ceramic materials plays an important role in its application.

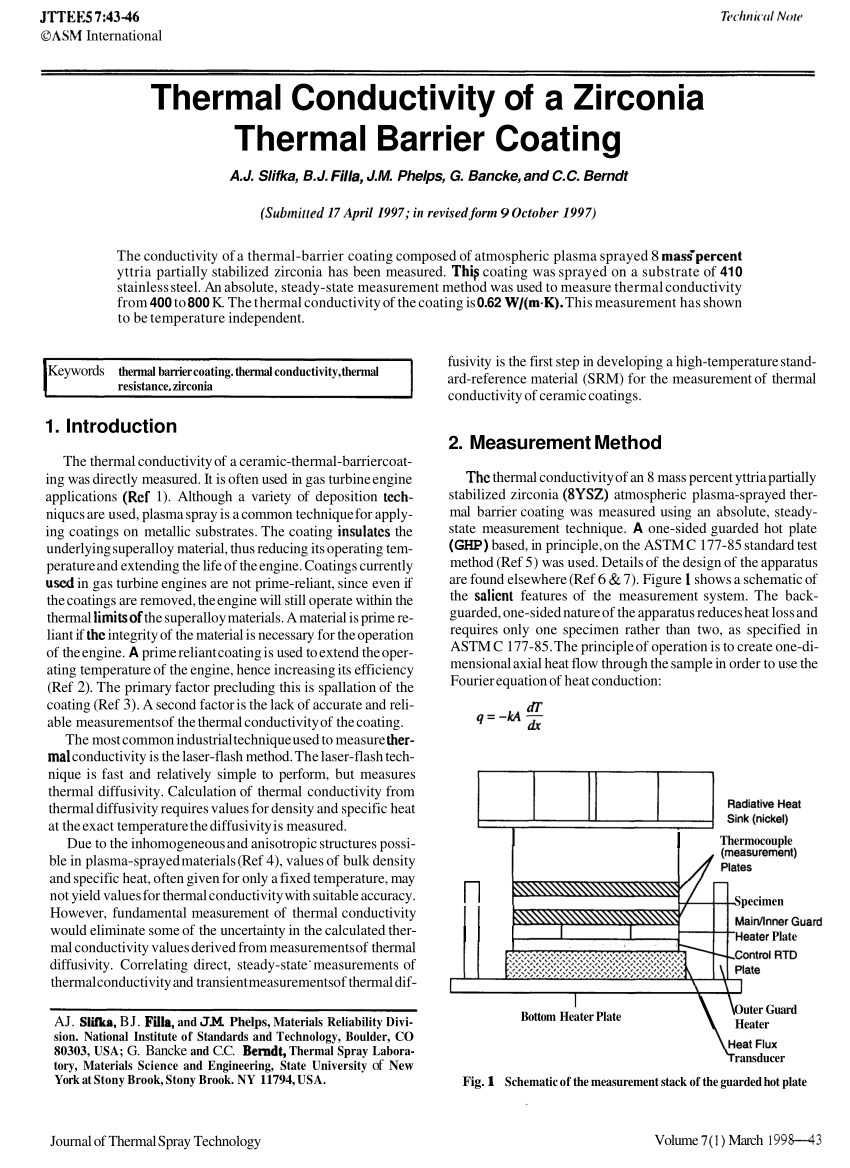

1 2 five thermal properties specific heat capacity thermal conductivity thermal diffusivity thermal expansion and emittance emissivity are presented in terms of their definitions and general test methods.

The relationship between thermal properties and the composition microstructure and processing of advanced ceramics monolithic and composite is briefly outlined providing guidance.

The problem with the thermal conductivity of ceramics is the dependence on the composition grain size and manufacturing process which make it rather difficult to obtain a reliable value from literature only.

Broadly speaking uhtcs are borides carbides nitrides and oxides of early.

Our product is available in various grades mainly as ceramic circuit substrates for power modules requiring high thermal conductivity and electric strength including a standard type 150 w mk and a high thermal conductivity type.

Ultra high temperature ceramics uhtcs are a class of refractory ceramics that offer excellent stability at temperatures exceeding 2000 c being investigated as possible thermal protection system tps materials coatings for materials subjected to high temperatures and bulk materials for heating elements.

Heat sink ceramic insulator description.

The heat conduction coefficient is high and the stability is good.

Thermal conductivity of ceramic measurement results the thermal conductivity and thermal resistivity values measured by the tls 100 are listed in table 1.

Alumina heat sink ceramic insulators are widely used in electrical and electrical fields that require heat conduction heat dissipation insulation high temperature resistance and high voltage breakdown.

Denka an plate is a high thermal conductivity ceramic substrate based on aluminum nitride having thermal conductivity several times greater than that of alumina.