In each case the exact value depends of course on the ambient con ditions and the admissible power loss.

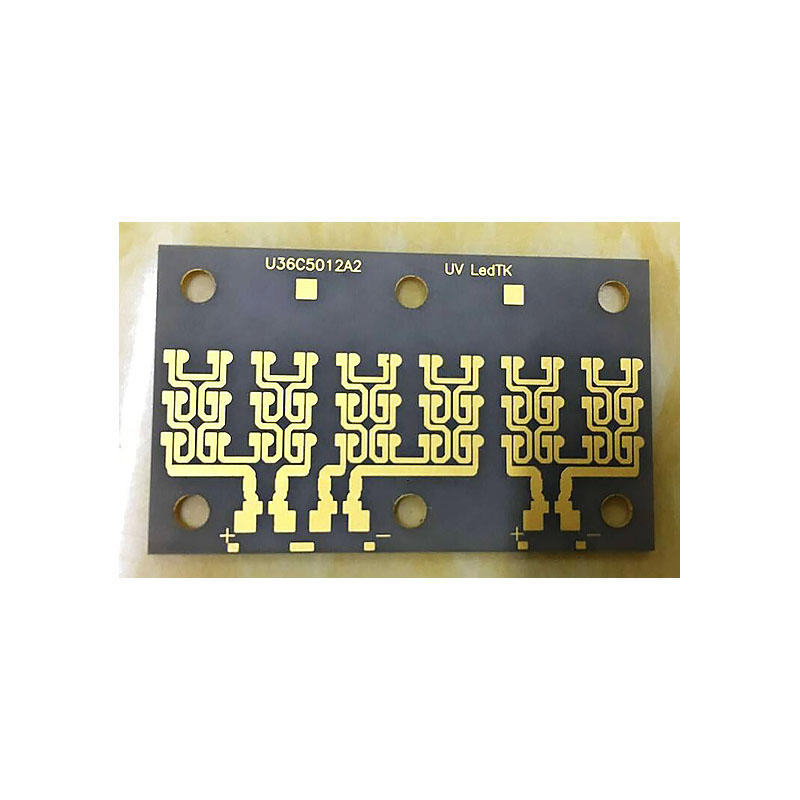

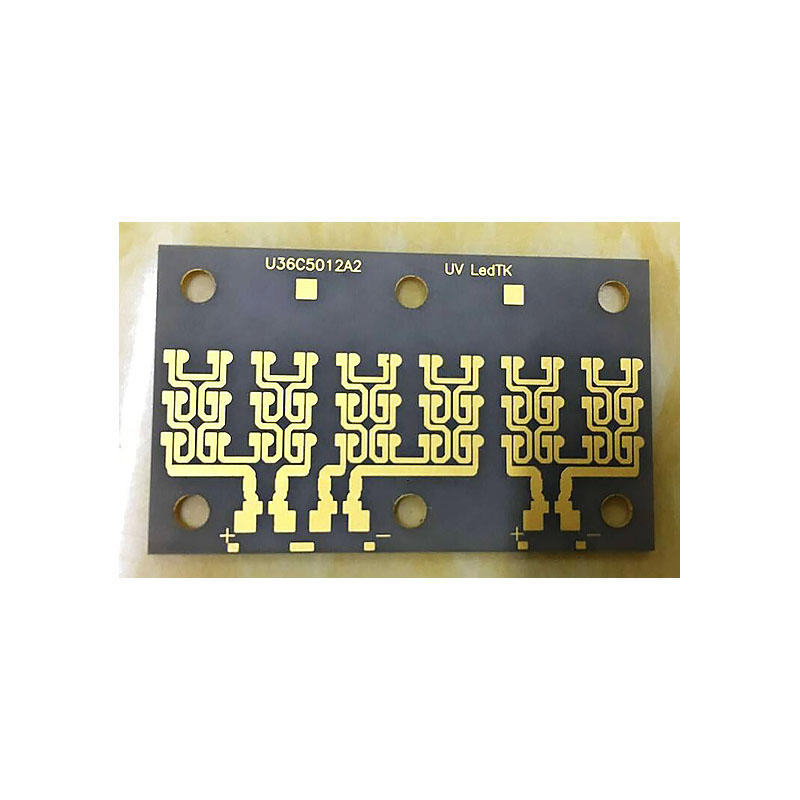

Ceramic inlay pcb.

Resins offering superior physical properties than the latter as the limited degree of polymerization conversion of direct.

Use the following process to come up with your ceramic pcb prototype.

Cercuits specializes in making it easy for you to order and use ceramic pcb substrates.

With the inlay board a greater heat output can be dissipated.

Best heat transfer from top to bottom side of the pcb.

Ceramic printed circuit board prototyping.

Ceramic inlays are stronger than direct posterior composite.

Copper inlay pcbs product information copper inlay pcbs standard pth pcb with copper coin inlays.

Printed circuit board faqs.

Best technology is the professional manufacturer of metal core pcb ceramic pcb fr4 pcb esp heavy copper pcb 0 15 0 30mm extra thin pcb rigid flex and pcba smt full turn key service in china with more than 11 years of experience always reply within 12 hours with best service at good price.

Advantage is a hot spot cooling on the pcb.

Copper inlay pcb copper inlay pcb can release heat from heater elements mounted on an electronic circuit board through copper inlays to a bottom side heat sink.

Maximum inlay thickness of 2 0 mm continuous currents of 600 a and peak currents of 1 200 a are achievable.

If you want to use pcb in high pressure high insulation high frequency high temperature and high reliable and minor volume electronic products then ceramic pcb will be your best choice.

Our unique set up allows us to produce small volume prototype batches efficiently and our online portal allows you to generate quotes in seconds order without the wait.

What is the difference between ceramic pcb fr4 boards mcpcb.

How can contact be made with an inlay board.

Because it makes optimal use of the thicker and above all wider copper surface.

Prototyping usually paves the way for the actual assembly of your ceramic pcb.

When you are looking for substrates for electronic circuits with a high thermal conductivity and a low expansion coefficient cte ceramic pcb will be your preferred choice of material.

In a cavity for example a component with high heat loss output can be securely positioned in the inlay board.

In addition components can be mounted on the upper part of the through hole by plating that part.

Pcb with hotspots under the components.

Thus the larger cooling surface overall and the simpler populating.

There s certainly nothing wrong with fr4 boards and if you ve been using them effectively in your business.