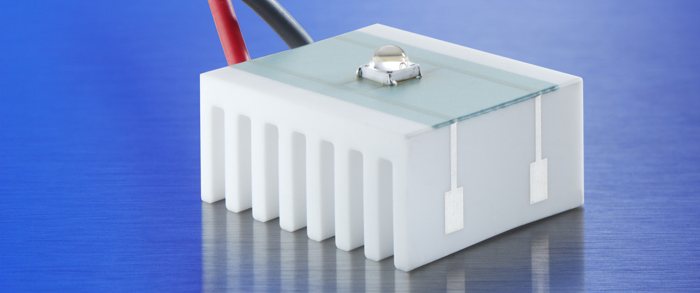

The ceramic heat sink ceramcool is an effective combination of circuit board and heat sink for the reliable cooling of thermally sensitive components and circuits.

Ceramic heatsinks vs aluminium.

Which one to get copper or aluminum.

One with heat pipes that stopped at the edge of the components and the other with heat pipes that ran above the components.

Aluminum heatsinks and look at a few different factors that play into aluminum s popularity.

Analysis demonstrated that the design with heat pipes running above the components kept junction temperatures within 2 c of the original.

Coating for aluminum heat sink.

Fr4 pcb material is not.

Aluminum alloys are the most common heat sink material.

This is because aluminum costs less than copper.

Aluminum is the most common material for heat sinks.

Each has its own advantages.

Heatsinks play an important role in helping to cool electronic devices.

Heat sinks are usually made from aluminum or copper.

If you are using your boards in applications where heat is a real issue like led lighting you will probably want to move away from standard fr4 boards towards ceramic boards or other metal core pcbs as metal core.

Hi i have a sealed aluminium case with chromate conversion coating cl3 containing a pcb that can reach temperatures up to 110 c 230 f.

Ceramic pcbs like aluminum nitride aln and aluminum oxide al203 are extremely thermally conductive.

Ats engineers used analytical modeling and cfd simulations to examine the thermal performance of two aluminum heat sink designs.

In particular extruded aluminum heat sinks fit the needs of most projects.

Heat sinks are also used in high power devices like power transistors lasers and light emitting diodes leds.

E coating is a generic term and has many industry names.

Most heatsinks are aluminum but some are made from copper.

Let s compare copper vs.

Heat sinks are designed to maximize the surface area in contact with the coolant fluid.

Let s talk about the main differences between them.

Electro painting electro coating e coating electro coating primer electrophoretic lacquering cathodic electrodeposition ced coating and cationic epoxy.

It enables the direct and.