The microstructure is the structure level of approximately 0 1 to 100 µm between the minimum wavelength of visible light and the resolution limit of the naked eye.

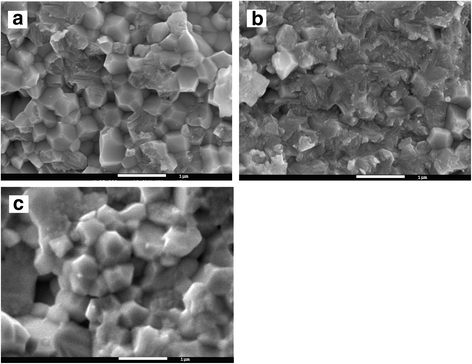

Ceramic fracture microstructure.

Some studies about ceramics had demonstrated that changing the grain size properly can make the fracture energy increased by one order of magnitude.

Improvements in properties depend on.

Microstructures solid solution.

Fracture resistance improved thermal shock resistance and resistance to erosion.

Fracture mechanics of ceramics discontinued series although this series no longer publishes new content the published titles listed below may be still available on line e.

Ceramography is the art and science of preparation examination and evaluation of ceramic microstructures.

In the case of a glass material the microstructure.

However the fracture toughness of tizrnbtamo c ceramic is only 3 28 mpa m 1 2 which is not obviously improved due to the lack of effective.

The microstructure includes most grains secondary phases.

The theme of the symposium was focused on the mechanical behaviour of advanced ceramics in terms of the cracks particularly the crack microstructure interaction delayed failure environmental effects in fracture.

A major field of academic study in the field of engineering ceramics relates to what is known as structure property relationships.

Microstructure which is too small to be seen with the naked eye plays an important factor in the final property of a material.

Fracture toughness of the composite in both directions.

To compare the fracture mechanics microstructure and elemental compo sition of lithography based ceramic manufacturing with pressing and cad cam.

Confirming the important relationship between the microstructure of an engineering ceramic and measured properties such as strength toughness or hardness.

The measured hardness values of tizrnbtamo c ceramic are 25 3 gpa at 9 8 n and 31 3 gpa at 100 mn respectively which are clearly higher than those of other available high entropy carbide ceramics.

Disc shaped specimens 16 mm diameter 1 2 mm thick.

Therefore the propagation of crack suffered from the effect of deflection leading to the increasing resistance of fracture.

For ceramics the microstructure is made up of small crystals called grains.

Special attention was paid on the novel methods in fracture mechanics testing pre standardisation and standartisation.

A classification based on the microstructure of ceramics with the inclusion of how the ceramics are processed which affects durability.

Ceramography can be thought of as the metallography of ceramics.

2 phase analysis fig 3 shows the x ray micrographs of stg 1 composite before and after hot pressing sintering.