However long term storage of surface mount multilayer capacitors can cause aging of dielectrics class ii dielectrics solderability problems and degradation of tape and reel.

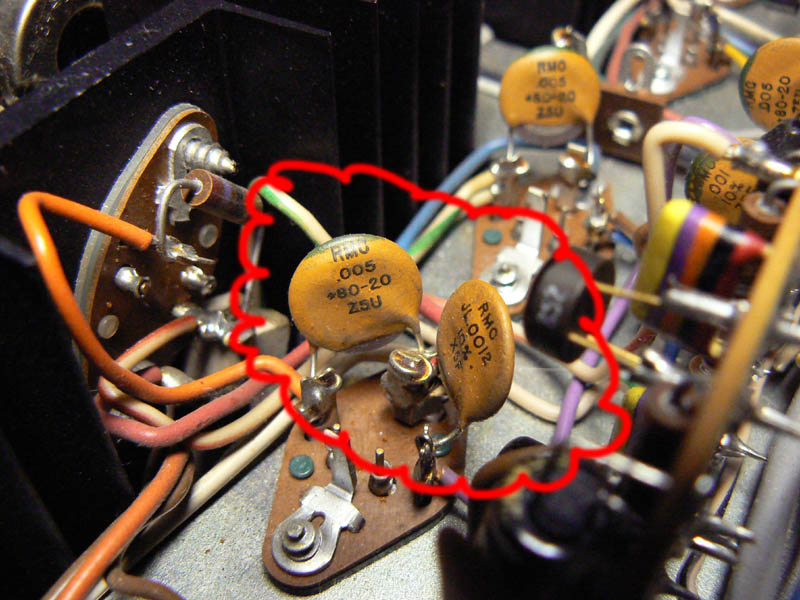

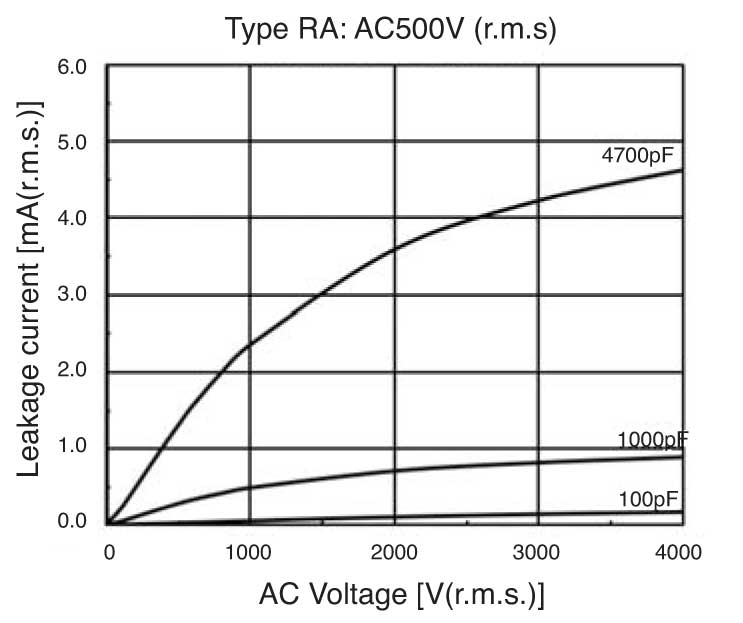

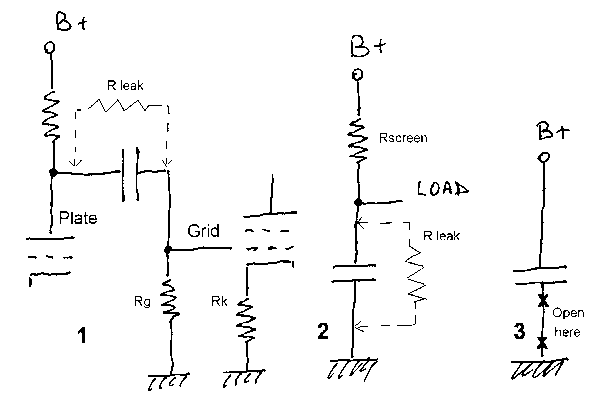

Ceramic disc capacitor white leakage.

The tantalum capacitor exhibits linear capacitance change with respect to temperature.

Replacing capacitors with low leakage units is always a good idea.

Do disc caps leak like electrolytics.

Around 20 ppm c and ceramic with a cte of 10 12 ppm c.

Under normal testing with a digital capacitance meter or an analog meter will not revealed any symptoms and you may think that the ceramic capacitor that you checked is ok.

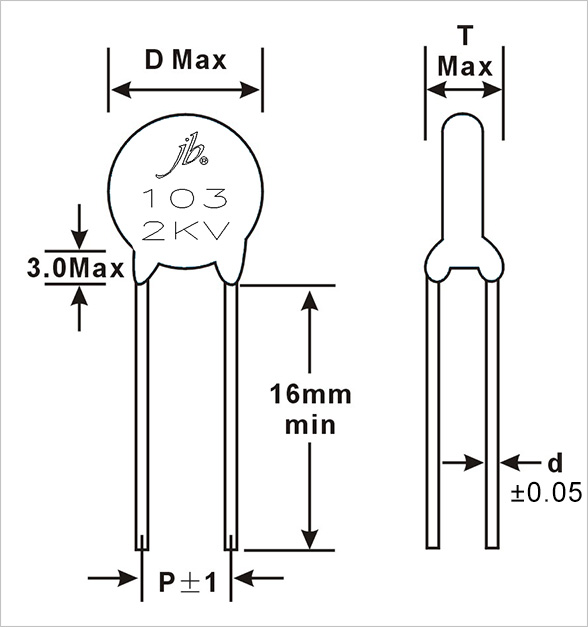

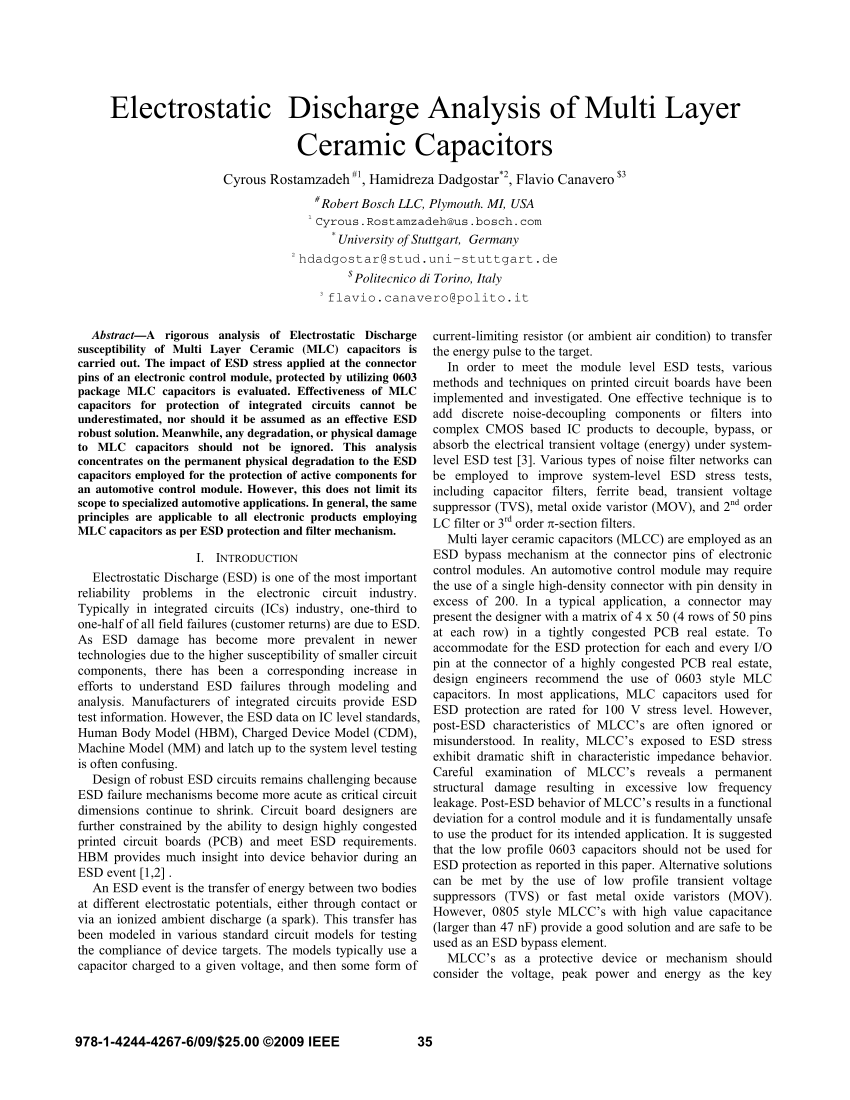

A ceramic capacitor is a fixed value capacitor where the ceramic material acts as the dielectric it is constructed of two or more alternating layers of ceramic and a metal layer acting as the electrodes the composition of the ceramic material defines the electrical behavior and therefore applications.

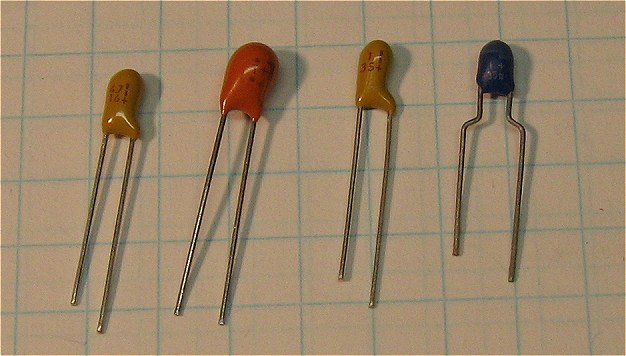

Ceramic capacitors and film capacitors.

5 capacitance change at 55 c to 8 at 125 c.

I believe the reason would be to keep it away from the larger power resistor which might damage it more.

Finally capacitors exhibit a curious behavior called dielectric absorption or da the capacitor acts as though it has a memory.

Ceramic multilayer capacitors have lots of layers of conductor and ceramic slurry in between them and tantalum capacitors have the element ta as its conductor plate.

Typical values of ceramic disc capacitor the ceramic capacitor leakage quite often happened when there is a high voltage applied into it.

The electrolyte discharge can also be larger covering the top of the cap with a dried substance which can be black orange brown white or a similar colour.

Ceramic capacitors have better characteristics than most other capacitors but they are not nearly as capacitively dense as electrolytics or tantalum capacitors.

So is it possible that the disc capacitor was purposefully hot glued to a power resistor.

Ceramic capacitors are generally a disk type in thru hole versions and a small rectangular device in surface mount types.

This tendency is made worse by ag pd being a much better conductor of heat 400 w m k than ceramic 4 5 w m k so that a thermal gradient will exist across the ceramic layer.

The key to making a capacitor is getting two plates with the largest possible area as close as possible to each other without them conducting to each other.

Figure 5 illustrates the typical capacitance response over temperature for tantalum capacitors class 2 ceramic x7r capacitors and class 1 ceramic np0 or c0g capacitors.

This can be accompanied by a tiny deposit of dried electrolyte in the middle of the top.

Unlike aluminum electrolytic capacitors the dielectric material of multilayer ceramic capacitors mlccs does not exhibit failures when the capacitor is stored for a short period of time.