A bearing is a machine element that constrains relative motion to only the desired motion and reduces friction between moving parts the design of the bearing may for example provide for free linear movement of the moving part or for free rotation around a fixed axis.

Ceramic bearings wikipedia.

Magnetic bearings support the highest speeds of all kinds of bearing and have no maximum relative speed.

Ceramic bearings can run lubrication free.

Although bearings had been developed since ancient times the first modern recorded patent on ball bearings was awarded to philip vaughan a welsh inventor and ironmaster who created the first design for a ball bearing in carmarthen in 1794.

For instance they are able to levitate a rotating shaft and permit relative motion with very low friction and no mechanical wear.

This is because ceramic materials don t micro weld.

Using technology developed as part of nasa s space program in the 1990s our hybrid bearings are made with top grade silicon nitride ceramic balls making them 58 lighter and 30 50 faster than traditional steel bearings.

In 1996 for machine tools and many other applications.

A magnetic bearing is a type of bearing that supports a load using magnetic levitation magnetic bearings support moving parts without physical contact.

They are used to attach the trucks and any type of risers to the board.

This degrades the surface and substantially reduces the bearing life.

A ceramic material is an inorganic non metallic often crystalline oxide nitride or carbide material.

The production of each ball takes from 50 to 70 days but the result is worth the wait.

Or it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts.

These bearings consist of a static bearing shrink fitted in its metallic environment and a rotating shaft sleeve mounted on the shaft.

Some elements such as carbon or silicon may be considered ceramics ceramic materials are brittle hard strong in compression and weak in shearing and tension.

His was the first modern ball bearing design with the ball running along a groove in the axle assembly.

Growth is estimated at 40 per year but could be even higher if ceramic.

They withstand chemical erosion that occurs in other materials subjected to acidic or caustic environments.

One of the earliest and best known rolling element bearings are sets of logs.

Around 15 20 million si 3 n 4 bearing balls were produced in the u s.

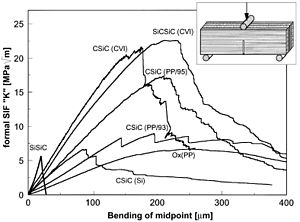

Under compressive stress the ceramic static bearing has a low risk of failure but a sic shaft sleeve does not have this situation and must therefore have a large wall thickness and or be specially designed.

Each bearing usually contains 7 steel or ceramic bearing balls although other configurations are used as well.

4 bearings are still 2 5 times more expensive than the best steel bearings their superior performance and life are justifying rapid adoption.